Our Products

Instrumentation Guages

Pressure Gauges

- Pressure gauges are a popular measurement tool used to keep track of pipeline pressure and ensure the safe flow of gases, liquids, and steam. Pressure gauges are used to evaluate the capabilities of pumps, conveying systems, and various spray nozzle types.

- Max-Seal is one of the leading manufacturer of pressure gauges and offer you the right pressure measuring instrument for your application.

- Bourdon Tube Pressure Gauge

- Solid Front Pressure Gauge

- Phenol Case Pressure Gauge

- Capsule Pressure Gauge

- Schaffer Diaphragm Gauge

- Commercial Pressure Gauge

- Utility Gauge

- Bourdon Tube Gauge

- Solid Front Gauge

- Phenol Case Gauge

- Capsule Gauge

- Schaffer Diaphragm Gauge

- Commercial Gauge

- Utility Gauge

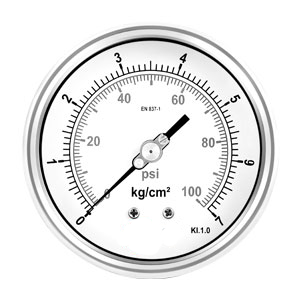

Description

Bourdon tube pressure gauges are the most frequently used mechanical pressure measuring instruments. A bourdon tube is used to measure pressure in a system, giving the user visual indication of the pressure level, ensuring the amount of pressure doesn’t exceed the maximum level or stoop too low. when an elastic transducers subjected to a pressure, it defects. The reading is visual and appears on a dial face at the front of the pressure gauge.

Description

A solid partition wall between the front of the gauge and the Bourdon tube system will redirect the released energy to the back of the gauge in which the blow-out back of the safety case design redirects any lose parts or media to exit through the back of the gauge. The solid front gauge is reinforced at the front, providing a blow-out back safety case design. Usually Solid front s are used for services having very high process pressure.

Description

Phenolic gauges have a high level of operator safety. The safety design consists of a solid wall between the pressure sensing element and window, and often a blowout back which protects the user from fluid and particles in the event of failure. Phenolic pressure gauges are generally used within aggressive environments such as chemical and petrochemical processing, food and beverage processing industries, plastic and paper manufacturing plants, oceanographic engineering. They are generally manufactured with stainless steel wetted parts that provide corrosion resistance.

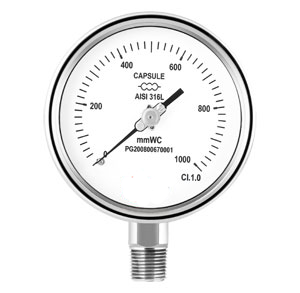

Description

Low pressure and vacuum capsule gauges are manufactured with a bellow type element, instead of a bourdon tube, which enables the gauges to deal with the very low pressure and vacuum ranges more efficiently.

Description

The schaffer diaphragm gauge is used for measurement of gas or liquids, and is well suited for use on corrosive, polluted or highly viscous mediums. These instruments are more reliable and easy to protect against overpressure than the Bourdon tube type The measuring element consists of one circular diaphragm clamped between a pair of flanges. It have a Diaphragm which displacement is transferred via a link to the movement.

Description

Commercial gauges are general purpose pressure measuring instruments commonly used in Heating Ventilation Air Conditioning (HVAC) and Refrigeration. Industrial pressure gauge is suitable for production processes that would not block the pressure system. Industrial gauges are used in manufacturing industries, OEM applications, hydraulic, water treatment and RO industries. The movement provides superior resistance to shock, vibration and pulsation, extends product life and reduces maintenance costs.

Description

API Utility pressure gauges covers a series of dry pressure gauges used for utility services as cost effective solutions. Dry pressure gauges find their application when there is a need to measure gas, water, oil or any medium not corrosive to brass materials. This model is constructed from a black mild steel (powder coated) case with a lens which is shatter-proof. These pressure gauges have geometrically balanced dial designs, thus a much easier reading experience.

Pressure Transmitter

The pressure or level of industrial liquids and gases is measured using pressure transmitters. A control system receives the output. Your plant will run safely, dependably, and profitably thanks to accurate and steady process measurements.